Best iame x30 Piston Assembly: Quality Parts Guide

Wondering how the iame x30 piston assembly works and how to install it correctly? This guide will cover its components, the installation process, and maintenance tips to keep your engine running smoothly.

The piston pin plays a crucial role in the iame x30 piston assembly, ensuring proper function and longevity.

Key Takeaways for iame x30

-

Iame x30 piston assembly is renowned for its outstanding durability and performance, playing a crucial role in enhancing engine efficiency and power output.

-

The assembly consists of key components like the piston, piston rings, connecting rod, and piston pin, with the piston crafted from high-strength aluminium alloy and featuring a chromium-plated ‘L’ ring for enhanced endurance.

-

Proper installation and maintenance are essential, requiring precise measurement, clean working conditions, and regular inspections to ensure sustained high performance and avoid engine damage.

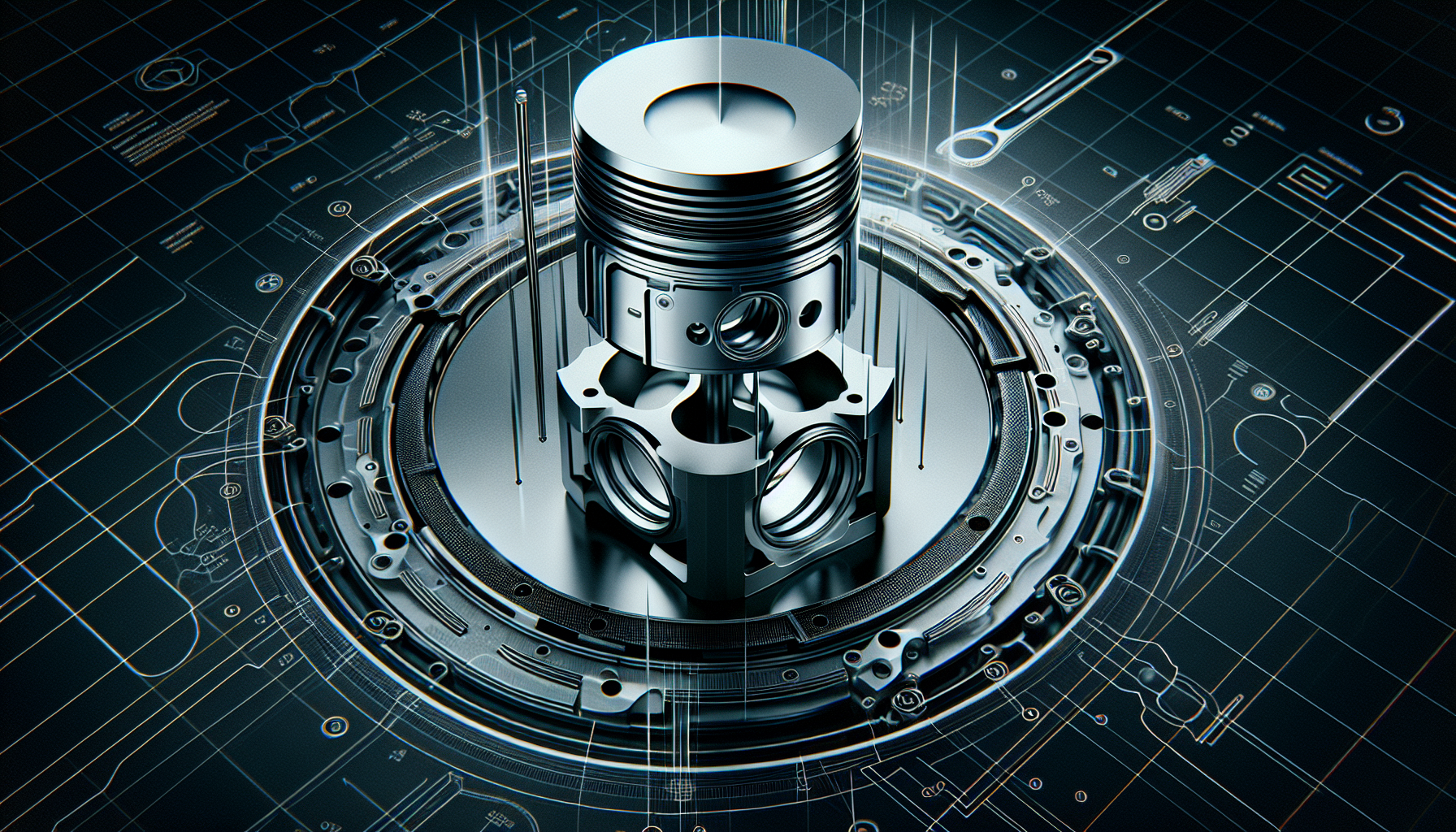

Introduction to Iame X30 Piston

When it comes to the iame x30 piston assembly, you’re looking at a masterpiece of engineering that balances strength with sophistication. Meteor Piston’s relentless pursuit of perfection has resulted in a product that stands out for its high quality standards. It’s not just about durability; it’s about delivering high performance at prices that won’t send your budget into a tailspin.

This piston assembly doesn’t just contribute to the engine’s performance; it’s a driving force behind the overall efficiency and power output, designed to push the limits with a high power level and an impressive torque diagram, even without the need for a power valve. The assembly includes the piston pin, which is crucial for its optimal function. It’s no wonder that some engines come equipped with Meteor pistons right from the get-go, a testament to their reliability and performance prowess.

Understanding the iame x30 Piston Assembly

The iame x30 piston assembly primarily functions to convert expanding gas energy into mechanical motion, acting as the engine’s driving force. Known for its precision, this assembly significantly impacts the engine’s performance, efficiency, and power output.

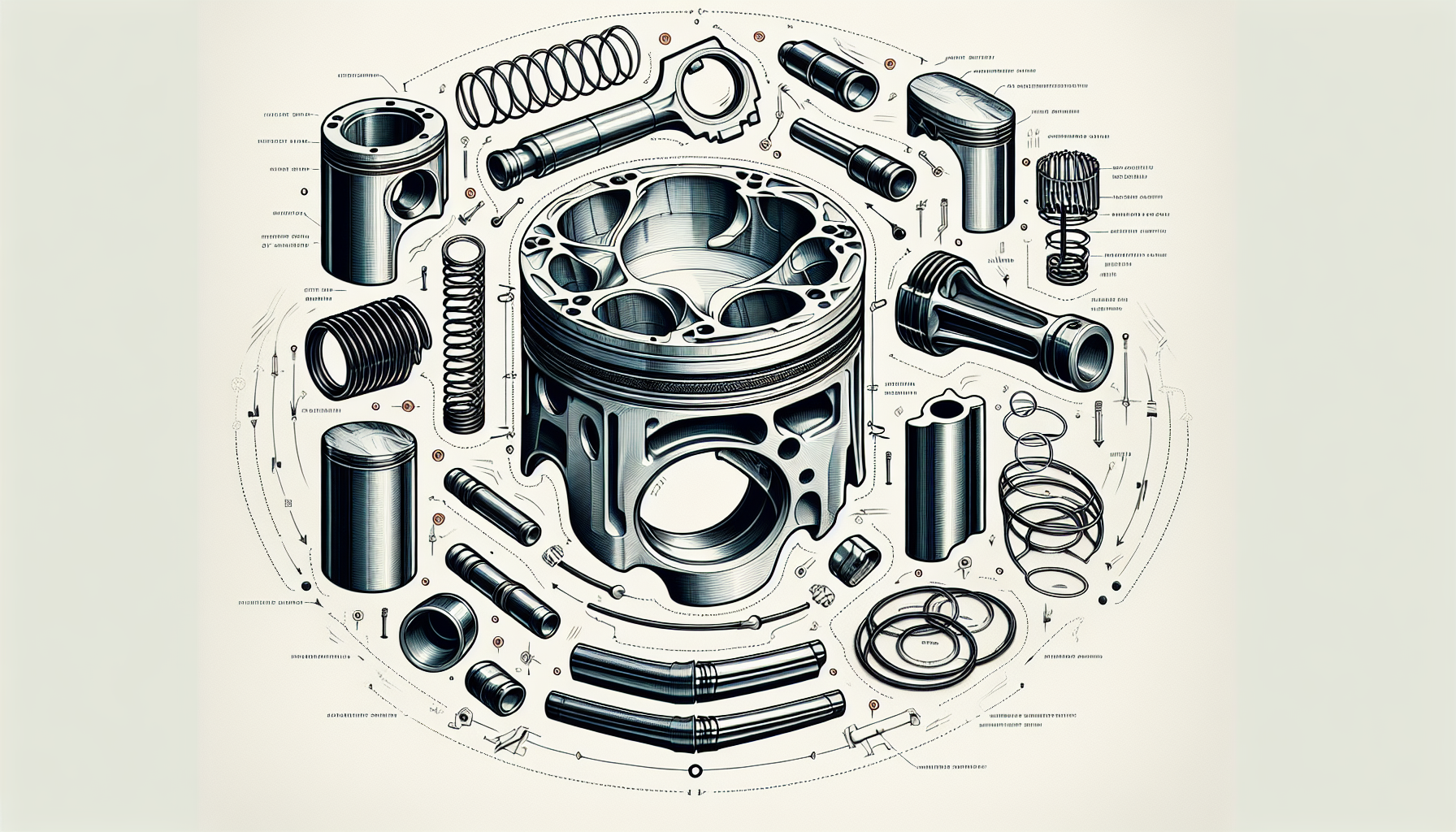

The iame x30 piston assembly embodies resilience and performance, assembled from several key components like the piston, piston rings, and connecting rod. The piston pin plays a crucial role in connecting the piston to the connecting rod, allowing for smooth pivoting motion. Meteor Piston showcases its commitment to quality through its two distinct piston versions for the iame x30: a lightened Racing version and a standard version designed for enhanced resistance and durability.

Key Components of the iame x30 Piston Assembly

An intricately designed puzzle, the iame x30 piston assembly consists of several critical pieces that must fit together perfectly to ensure the engine’s peak performance. One such critical component is the piston pin, which plays a vital role in the overall functionality of the assembly.

Now, let us turn our attention to the pieces of this puzzle, starting with the piston and its accompanying rings.

Piston

The piston, at the core of the iame x30 assembly, is a fine example of engineering ingenuity. It is:

-

Cast from a high-silicon alloy for enhanced strength and performance

-

Meticulously designed to withstand the rigors of racing

-

Made from a high-strength aluminum alloy used in gravity casting, giving it the resilience needed to handle the intense conditions it faces.

The piston pin connects the piston to the connecting rod, playing a crucial role in the engine's operation.

Not only is the material choice crucial for durability and efficient heat dissipation, but so too are the specific measurements and design features. With a chromium-plated ‘L’ ring for added endurance and a precise 17.5mm measurement from the skirt’s bottom for consistent performance, the iame x30 piston is a testament to thoughtful design. It’s this attention to detail, ensuring proper fitting and clearance, that underpins the engine’s optimal performance and longevity.

Piston Rings

Piston rings are the unsung heroes that seal the combustion chamber, maintaining compression and preventing gas leakage. In the iame x30, these rings are designed to withstand the high pressures of combustion gases, ensuring the engine’s integrity. With two primary types, the compression ring and the oil control ring, each serves a distinct yet vital role in the engine’s function.

The ‘L’ ring, specifically designed for the iame x30, is chromium plated, marrying durability with performance to meet the demands of high-level racing. Available in various sizes, these rings are precision-fitted to the engine, a testament to the customizable nature of iame x30’s design.

Installation Process for iame x30 Piston Assembly

The journey from individual parts to a fully functioning piston assembly is meticulous and requires precision every step of the way. Whether you’re a seasoned mechanic or a dedicated enthusiast, the installation process is a critical phase that demands attention to detail. One crucial aspect is correctly installing the piston pin during the assembly process to ensure optimal performance and longevity.

We will now examine the necessary preparations and steps for a successful installation.

Preparation

Setting the stage before the actual assembly is fundamental. Organizing the workspace paves the way for a smooth installation. Gather the necessary tools, including:

-

a real honing machine

-

dial indicators

-

piston ring compressor

-

torque wrenches

Ensure your environment is clean and well-lit to prevent any contamination of the delicate engine components.

A clean workspace is not just about aesthetics; it’s about safeguarding the integrity of the piston assembly. Any foreign matter can compromise the installation, leading to potential engine failure. Therefore, meticulous cleaning of the area and the components themselves is a non-negotiable first step in the process.

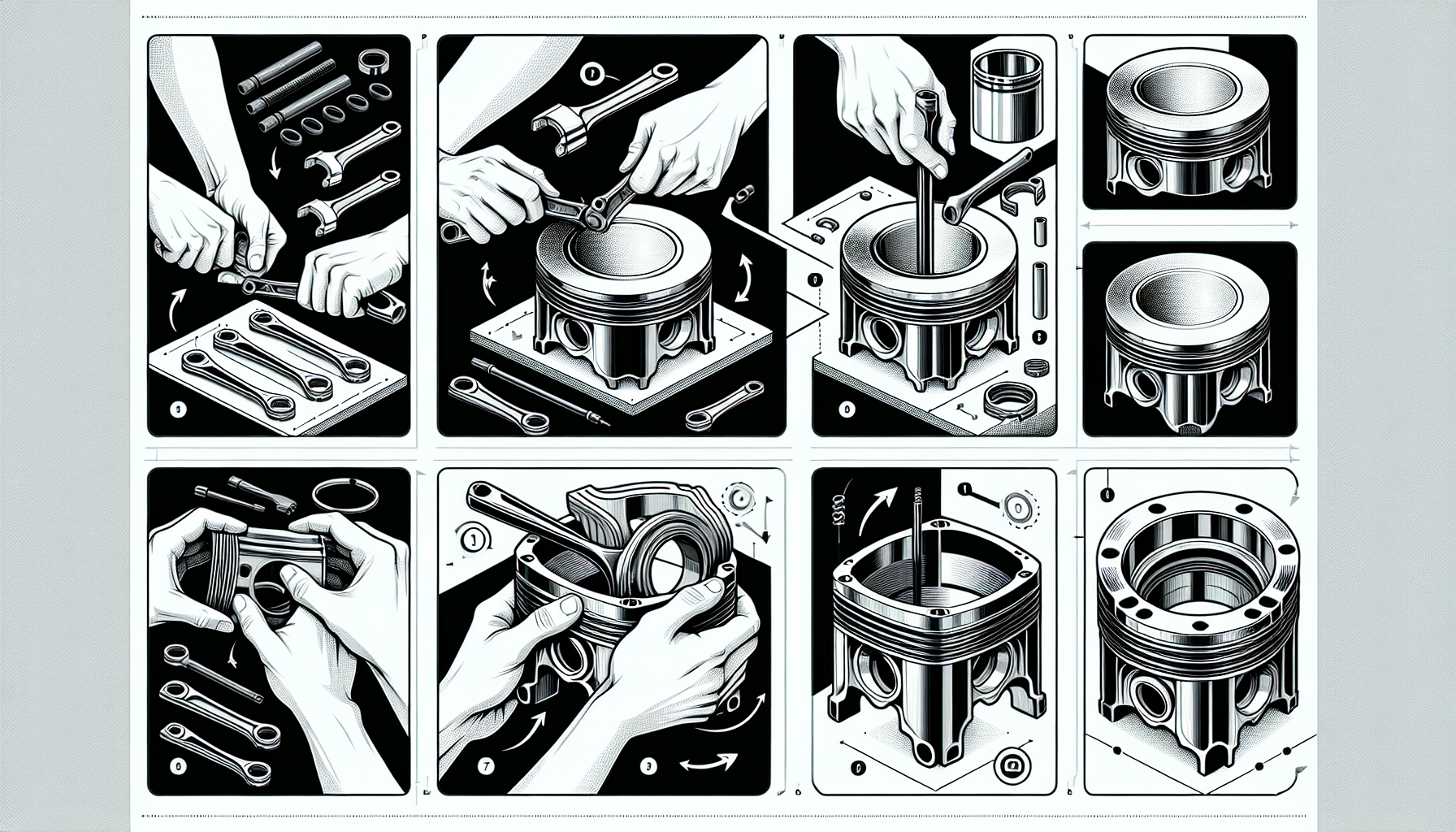

Assembly Steps

As we begin the assembly, the initial step involves honing the cylinder using an appropriate honing machine - drill hones should be avoided to maintain precision. Once honed, measure the finished bore and select a piston that is 0.11mm to 0.12mm smaller to ensure the perfect fit. Using a micrometer, the piston is measured to determine its exact size, which is critical for fitting within the cylinder.

With precision at the forefront, follow these steps to properly assemble the piston and connecting rod:

-

Apply a light coat of engine oil to both the piston and the connecting rod before fitting them together.

-

Carefully position the piston rings in their grooves, avoiding twisting or overlapping.

-

Ensure the correct installation of the piston pin by aligning it properly and securing it in place.

-

Align the piston within the cylinder, ensuring that the arrow on the piston’s top points towards the exhaust port.

By following these steps, you can ensure a proper assembly of the piston and connecting rod.

Common Mistakes to Avoid

The path to a successful installation is fraught with potential pitfalls, and awareness is your best defense. Steering clear of a drill hone when working on the cylinder is a must, as such tools lack the precision necessary for a flawless build. Equally important is ensuring that the piston size is on point; an ill-fitting piston can wreak havoc on your engine.

Over-tightening the piston rings or installing the piston in the wrong direction may seem like minor missteps, but they can lead to catastrophic engine damage. Furthermore, incorrect adjustments to the squish gap could adversely affect the engine’s compression and power output, making precision vital in every aspect of the installation process. Correctly installing the piston pin is also crucial to avoid engine damage.

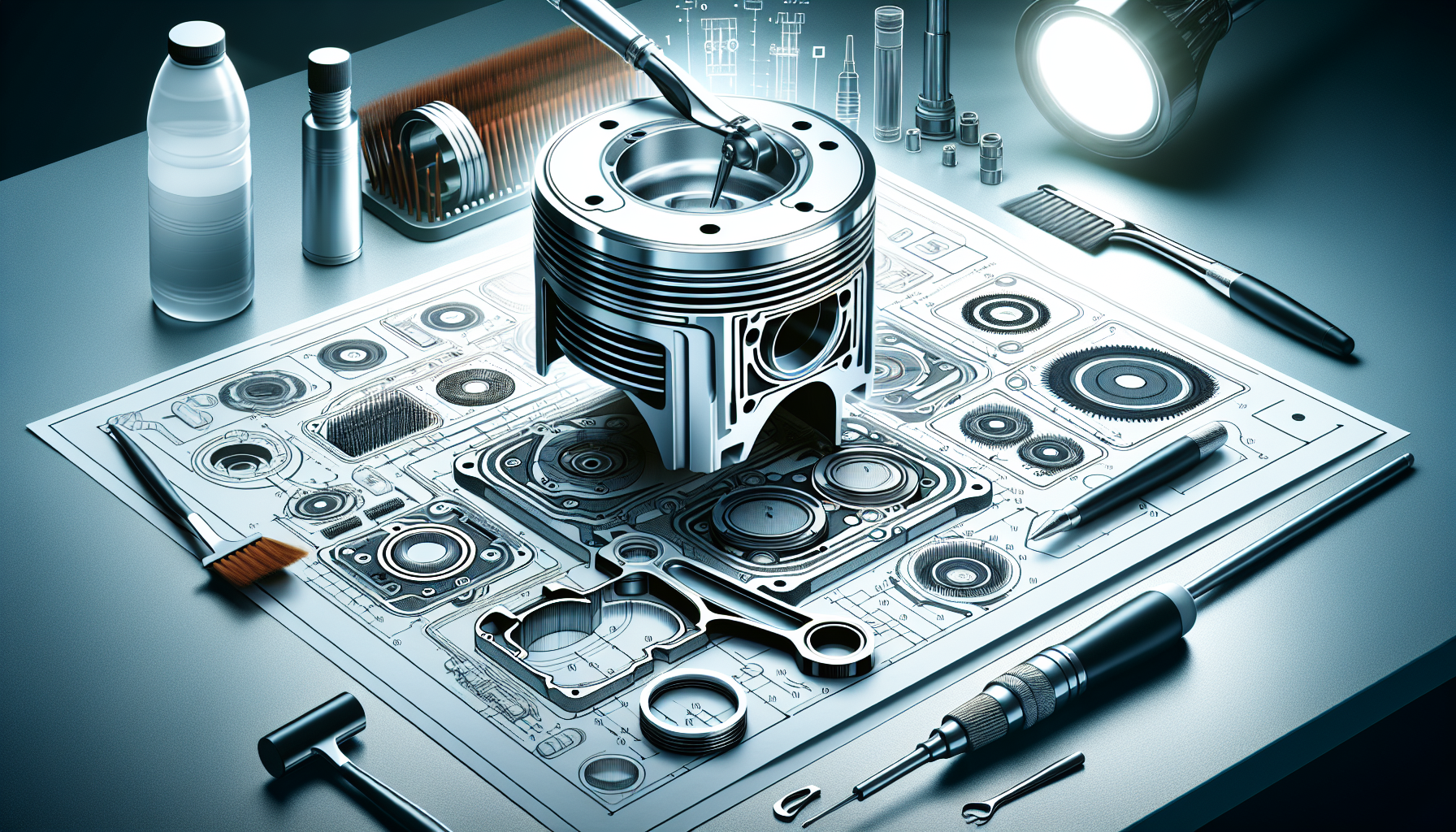

Maintenance Tips for iame x30 Piston Assembly

Once your iame x30 piston assembly is installed and running smoothly, maintaining its condition is essential for sustained performance. Regular maintenance should include inspecting the piston pin to ensure it is in good condition. We will now walk through the best practices, including regular inspections and proactive replacements, to keep your engine performing optimally.

Regular Inspection

Regular inspections act as the backbone of maintenance, crucial for identifying and addressing issues before they worsen. Here are some key steps to follow:

-

Examine the piston for cracks.

-

Measure its dimensions consistently to ensure it remains within the specified limits.

-

Check the condition of the piston pin.

-

Keep a log of the piston’s lifespan; tracking time can provide insights into performance trends.

Look beyond the piston skirt for wear signs; failure can strike with little warning and have dire consequences for the engine. Check the main bearings for movement and the crank run-out for deviations from acceptable limits.

Balance in the connecting rod is crucial for smooth operation, and signs of overheating or wear at the rod ends must be addressed without delay.

Cleaning Procedures

Maintaining cleanliness in the piston assembly goes beyond aesthetics; it serves as a protective measure against wear and degradation. A light hone can help maintain the bore shape and ensure the rings seat properly, preserving the integrity of the engine.

Always use a real honing machine for this task to achieve the desired precision and cleanliness.

Replacement Signs

Recognizing when to replace components of your piston assembly can save you from costly repairs and downtime. Watch for the following signs that may indicate the need for a new piston:

-

Piston wear, especially at the skirt, which could signal the need for a new piston to avoid motor damage

-

Excessive wear or damage to the piston

-

Any noticeable decrease in engine performance

-

Signs of wear on the piston pin, such as scoring or deformation, indicating the need for replacement

Being mindful of these signs will help you maintain your engine’s performance and prevent further damage.

Performance Enhancements for iame x30 Piston Assembly

Enhancing your iame x30 piston assembly’s performance can offer significant advantages if you’re looking for a competitive edge. Some ways to improve performance include:

-

Honing the cylinder on a proper machine

-

Fitting a precisely measured piston

Experiment with piston clearances and base gaskets to fine-tune your engine’s response. A thinner base gasket, for instance, can lower the exhaust port height, changing when peak power is achieved – an adjustment that can be particularly beneficial on tight and twisty tracks. Remember, the secret to unlocking your engine’s potential lies in the synergy between the right base gasket thickness, port height, and head volume.

Summary

As we draw this exploration to a close, let’s reflect on the iame x30 piston assembly’s journey from a collection of parts to the powerhouse at the heart of your engine. We’ve examined its robust design, detailed the precision required in its installation, and shared critical maintenance tips to ensure its longevity.

Caring for your iame x30 piston assembly is an ongoing commitment that pays dividends in performance and reliability. With the knowledge and insights gained, you’re now equipped to maximize the potential of your engine, ensuring it delivers the high-octane thrills you crave every time you hit the track.

Frequently Asked Questions

What is the primary function of the iame x30 piston assembly?

The primary function of the iame x30 piston assembly is to convert expanding gas energy into mechanical motion, driving the engine and contributing to its overall efficiency and power output.

What materials are used in the construction of the iame x30 piston?

The iame x30 piston is made from a high-silicon alloy and high-strength aluminum alloy, providing durability, performance, and efficient heat dissipation.

How often should I inspect my iame x30 piston assembly?

Inspect your iame x30 piston assembly regularly by checking for cracks, measuring dimensions, and examining the connecting rod and main bearings for wear or damage. This routine inspection is crucial for maintaining the performance of your engine.

What are the signs that indicate the need to replace parts of the piston assembly?

If you notice visible wear or damage to the piston, unusual noises, loss of power, or a decrease in engine performance, it may be time to replace parts of the piston assembly. Additionally, signs of wear on the piston pin, such as scoring or excessive play, also indicate the need for replacement.

Can modifications to the iame x30 piston assembly enhance performance?

Yes, modifications such as, piston clearances, and compression ratio adjustments can enhance the performance of the iame x30 piston assembly. These alterations can improve the overall efficiency and power output of the engine.

| SKU | X30PISTONASS |

Be The First To Review This Product!

Help other Trackside Karts N Parts users shop smarter by writing reviews for products you have purchased.